[[param]]heading=Robust Electronic Assembly Protection[[/param]]

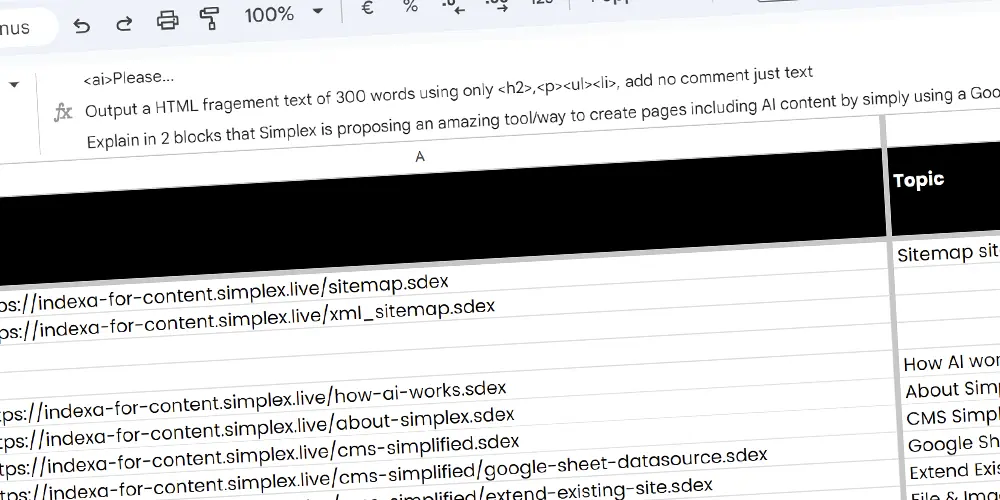

In the field of electronic manufacturing, overmolding is not just about enhancing the aesthetic and ergonomic attributes of electronic components—it's a critical process designed to significantly improve product durability and functionality. While the benefits of overmolding are well recognized in terms of protection and longevity, the technique itself involves intricate challenges that require expert understanding and precise execution.

[[tooltip-box]]Key Challenges in Overmolding for Electronics|

Material Compatibility:

- Issue: Selecting the right materials that bond well without compromising the integrity of the electronic components can be complex. The interaction between substrates and overmold materials must ensure chemical compatibility to avoid degradation.

- Nicomatic Solution: We use a rigorously tested selection of silicone-based resins and hotmelt materials that are proven to integrate seamlessly with various substrates, ensuring a durable bond and integrity of the assembly.

Thermal Management:

- Issue: Managing the heat generated during the overmolding process is crucial to prevent damage to sensitive electronic parts. Inappropriate heat management can lead to component failure.

- Nicomatic Solution: Our low-pressure injection technique minimizes heat exposure, while our materials are chosen for their excellent thermal stability, protecting components during and after the overmolding process.

Environmental and Mechanical Stress Resistance:

- Issue: Overmolded components must withstand diverse environmental conditions including extreme temperatures, moisture, and mechanical impacts.

- Nicomatic Solution: We engineer overmolding compounds that enhance resistance to these stresses, tailored specifically for the operational conditions the product will face.

[[/tooltip-box]]

Meeting Rigorous Industry Standards

Ensuring compliance with industry standards is not merely about following guidelines—it's about guaranteeing the overmolding provides real-world benefits:

- MIL-STD-83513: Products designed to meet military specifications must survive in the most demanding conditions, demonstrating our commitment to high-performance standards.

- EN9100 and ISO9001: These certifications signify our rigorous quality management system and operational excellence in the aerospace industry, where precision is paramount.

Innovative Overmolding Options at Nicomatic

At Nicomatic, we recognize that one size does not fit all when it comes to overmolding:

- Flexible Overmolding: Utilizing silicone-based resin, ideal for applications requiring both flexibility and high resilience against physical stresses.

- Rigid Overmolding: Employing low-pressure injection with hotmelt materials, suited for environments needing robust, impact-resistant casing.

Why Opt for Nicomatic’s Expertise?

Choosing Nicomatic means leveraging our deep understanding of overmolding’s technical challenges to ensure:

- Enhanced Product Longevity: Through strategic material selection and process optimization.

- Compliance and Reliability: Every solution adheres to stringent standards for unmatched performance.

Connect with Our Specialists

If you are looking to advance the protection and durability of your electronic assemblies through sophisticated overmolding techniques, Nicomatic is your ideal partner. Contact us to discuss how we can tailor our technology to meet your specific challenges and enhance your product’s performance.

Together, let's tackle the complexities of overmolding and transform challenges into opportunities for innovation and excellence in your electronic products.