[[param]]heading=High-Reliability Micro-Connectors for Extreme Space Environments[[/param]]

Introduction

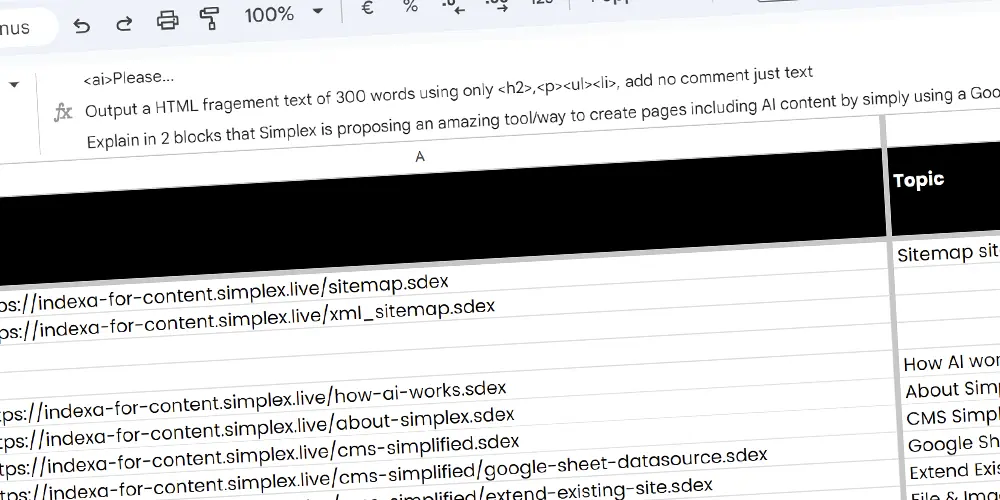

Nicomatic’s CMM connectors are engineered to deliver high performance and reliability in extreme environments, making them a preferred choice for aerospace and space applications. These micro-connectors are optimized for applications where ruggedness, lightweight, and compact design are essential, especially in high-stakes, resource-constrained environments like space.

Key Attributes for Space Applications

[[tooltip-box]]CMM Connector Attributes in Space| CMM connectors stand out in space applications due to their ability to withstand high vibration, temperature fluctuations, and mechanical stresses. [[/tooltip-box]]

- Vibration and Shock Resistance: In space launches and operations, components face extreme mechanical stresses. CMM connectors are certified to endure vibration levels up to 15 g RMS and shock resistance up to 100g for 6 ms.

- Temperature Tolerance: Space environments involve temperature extremes that demand robust materials. CMM connectors perform across a wide temperature range from -60°C to +260°C, ensuring operational stability in various space missions.

- Corrosion Resistance: Exposure to corrosive elements is mitigated with high-resistance materials and finishes, like tin or gold plating, which ensure that connectors maintain integrity even in the presence of potential contaminants.

- High Current and Voltage Ratings: In applications requiring strong electrical performance, CMM connectors offer up to 3A per contact and high insulation resistance, enabling reliable power delivery and data transfer under high-stress conditions.

Performance Advantages

[[tooltip-box]]Space Mission Durability| CMM connectors’ proven durability and resistance to harsh conditions make them ideal for long-duration space missions like satellites, space probes, and orbital stations. [[/tooltip-box]]

CMM connectors contribute to the reliability and miniaturization requirements in space applications by offering:

- Size and Weight Optimization: They deliver robust performance in a compact, lightweight form factor, essential for reducing payload mass—a critical factor in space launches and onboard operations.

- Flexible Configurations: The CMM series supports varied layouts and configurations, including mixed signal and power transmission within a single connector. This flexibility helps designers optimize space without compromising connectivity.

Real-World Space Applications

Nicomatic's connectors have been utilized in major space programs, including satellite systems and interplanetary missions, where reliability is paramount. Key clients, including agencies and aerospace companies, use these connectors for:

- Satellites: High-performance and weight-saving features make CMM connectors a staple in satellite communications and control systems.

- Deep Space Probes: Withstanding extreme environments over long durations, Nicomatic’s connectors provide essential durability for deep space exploration.

- Space Stations: Reliability in continuous use environments ensures stable performance for orbital equipment and modules.

Conclusion

[[separator-medium /]] [[tooltip-box]]Choosing CMM for Space| By providing miniaturization, durability, and high electrical performance, CMM connectors support mission-critical requirements, cementing Nicomatic's role as a trusted provider for space technology. [[/tooltip-box]]

CMM connectors underscore Nicomatic’s commitment to high-reliability interconnect solutions designed to thrive in the demanding environments of space, supporting critical systems in a compact and efficient format. For aerospace engineers, they offer a versatile and robust solution that meets rigorous space standards.