[[tooltip-box]]EMM Connectors|In today’s world of advanced electronic systems, the demand for connectors that are not only compact but also rugged and versatile is ever-increasing. Designed specifically to address these requirements, Nicomatic’s EMM connectors provide a high-performance interconnect solution that combines durability, modularity, and space efficiency. Here, we dive into what makes the EMM series stand out, along with the top applications where they bring tangible benefits to engineers and product developers.[[/tooltip-box]]

What are EMM Connectors?

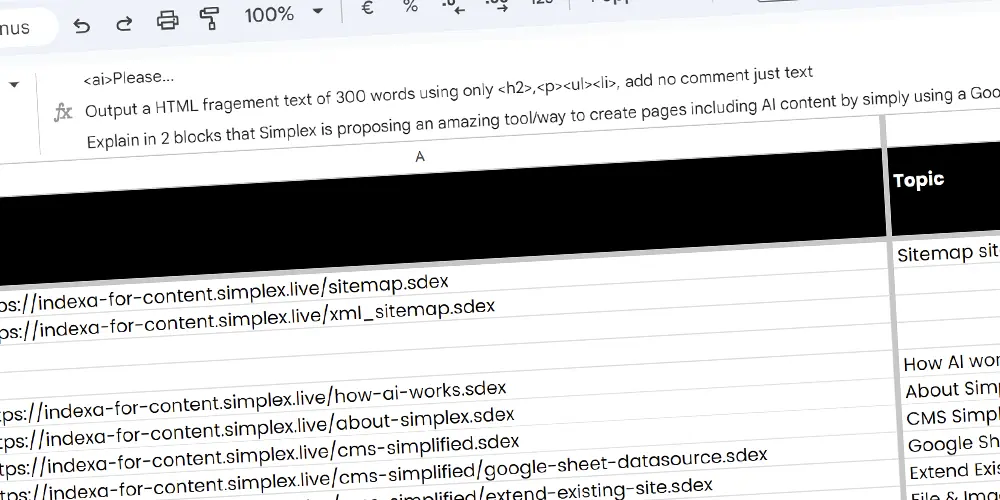

The EMM series by Nicomatic is a line of miniaturized micro-connectors, known for their reliability in harsh environments. Built to meet the stringent performance requirements of MIL-DTL-83513G and MIL-DTL-55302G, these connectors are engineered to be exceptionally durable and compact. They offer a remarkable 40% reduction in space compared to conventional Micro-D connectors, making them an ideal choice for applications where size and weight are crucial.

Key characteristics include:

- High Reliability: Compliant with military-grade standards, EMM connectors are tested to perform in extreme temperatures, shocks, and vibrations.

- Space and Weight Efficiency: At a 1.27mm pitch, EMM connectors achieve significant size reduction while delivering excellent electrical and mechanical performance.

- Modular Design: Available in multiple configurations, from 4 to 60 signal contacts, they support both PCB-to-PCB and PCB-to-cable applications.

- Versatile Mounting Options: EMM connectors are compatible with straight and 90° mountings, including thru-hole and surface mount (SMT) options.

These design features make EMM connectors a versatile solution in a wide array of critical applications, where robust and compact connectors are essential.

Top Applications for EMM Connectors

Given their compact and rugged design, EMM connectors are ideally suited for applications in challenging environments where reliability cannot be compromised. Here are the top applications where EMM connectors are frequently deployed:

- Aerospace Systems

- EMM connectors are widely used in avionics and satellite electronics. Their compact form factor helps save weight—a crucial factor in aerospace—while providing the reliable connections necessary for high-altitude and outer-space environments.

- Defense and Military Equipment

- Designed to withstand harsh conditions, EMM connectors perform well in military systems where connectors are exposed to constant vibrations, shocks, and high-temperature variations. They are used in communication devices, radar systems, and vehicle electronics within defense applications.

- Civil Aviation

- In the civil aviation sector, EMM connectors are incorporated into instrumentation and control systems. Their compact and lightweight nature helps optimize space in aircraft interiors, making them ideal for applications like in-flight entertainment systems and cockpit control modules.

- Space Exploration

- Space applications require connectors that can function reliably in the vacuum and temperature extremes of outer space. The EMM series meets these requirements with materials and designs that endure high-vacuum environments, making them suitable for satellite systems, telescopes, and space station equipment.

- Unmanned Aerial Vehicles (UAVs)

- UAVs, including drones, require lightweight, compact components to maximize payload and performance. EMM connectors are an excellent fit for these applications, providing durable connections for UAV navigation and control systems.

- Robotics

- Robotics applications in industrial and manufacturing environments benefit from EMM connectors’ modular design, which supports a wide range of configurations. They are used in robotic arms and automated systems where connectors are subject to constant motion and mechanical stress.

- Medical Equipment

- Medical devices, particularly portable or miniaturized equipment, require connectors that are compact yet reliable. EMM connectors are used in diagnostic devices, imaging equipment, and other medical electronics where space is at a premium, and failure is not an option.

- Railway Electronics

- Railway systems operate under conditions of high vibration and environmental exposure. EMM connectors, with their robust design, are frequently employed in railway electronics, including control and monitoring systems that demand high-reliability connections.

- Industrial Automation

- EMM connectors are a mainstay in automated industrial systems, providing reliable connections for machines that require frequent maintenance and durability across repeated connection cycles. Their compatibility with both PCB-to-PCB and PCB-to-cable applications enables flexibility in complex setups.

- Motor Sports

- In high-speed racing vehicles, connectors face extreme conditions, including shock, vibration, and exposure to varied temperatures. EMM connectors offer the robustness needed to maintain reliable connections in critical control systems, sensor arrays, and data logging equipment within motorsports.

Why Choose EMM Connectors?

The EMM series connectors stand out due to their compact, robust, and modular features that align with the needs of cutting-edge technology sectors. By offering high durability and military-grade reliability in a small form factor, these connectors solve space and weight constraints without compromising performance. With versatile mounting options and configurations that allow for easy integration into complex systems, EMM connectors are an invaluable asset in designing for today’s extreme environments.

Nicomatic’s EMM series is not just a product line; it is a solution for engineers and product designers aiming to push the limits of what’s possible in high-performance electronics. Whether for aerospace, medical, defense, or industrial applications, EMM connectors provide the reliability and compactness needed for success in even the most demanding scenarios.